To create a platform of sharing the applications, developments and needs of automotive smart display industry, Smart Display Industrial Alliance(SDIA)held a webinar with the topic, “2021 Automotive Smart Display Technology and Application” on July 8th, 2021. DEKRA iST was invited to talk about the challenges of automotive reliability.

General Lee, Director of engineering department of DEKRA iST, pointed out in the journey of new products development, DEKRA iST is a reliable partner to make sure the new products not only meet the expectation of your own company and also the market, but also meet the specifications. That’s the reason why reliability tests always play an important role. Along with the development of modern technology, the market of EV industry is getting more and more mature, and smart cars are also just around the corner, however, there’re still amount of challenges of reliability.

An electric vehicle is widely defined as a vehicle driven by electricity and classified into 4 types, battery electric vehicles (BEVs), Plug-in hybrid electric vehicles(PHEVs), hybrid electric vehicles(HEVs) and fuel cell electric vehicles(FCEVs). The basic powertrain structure of EV is that electricity passes through the AC/DC OBC (On Board Charger) on the vehicle and be stored in the battery. Then, AC and DC currents are separated by DC/AC Inverter and DC/DC Converter. The former is sent to the engine, and the latter is sent to the car's audio-visual system or display.

General Lee also shared a key number, “129,” of EV in 2021. Taiwan is expected to ban the sale of fuel vehicles in 2040 (The 86th year of the "Republic Era.) Countries are planning to ban the sale of fuel vehicles. New cars and vans powered wholly by gas and diesel will not be sold in Costa Rica from 2021. From 2030 to 2040, most countries would ban the sale of fuel vehicles, which means the trend of electric vehicles is predictable.

Due to the strict operation environment for vehicles, compared with commercial or industrial grade, both “product reliability lifetime” and “operating conditions” requires higher standard in automotive grade. For example, the temperature and humidity test must be increased to 1,000 hours, and the vibration test requires eight hours for each axis, which takes 24 hours to test all the axes.

Currently the major specifications for EV parts include UN ECE R100.2 (Regulation No. 100 Revision 2) formulated by ECE (Economic Commission for Europe). As for Car PCB, the major specifications include IPC TM-650 2.6.25. For PCB (Printed Circuit Board), to check whether there is a risk of CAF (Conductive Anode Filament). Under harsh environment, the migration of metal ions might accelerate on PCB. Once 2 pads are conducted, it might cause a short, which is risky.

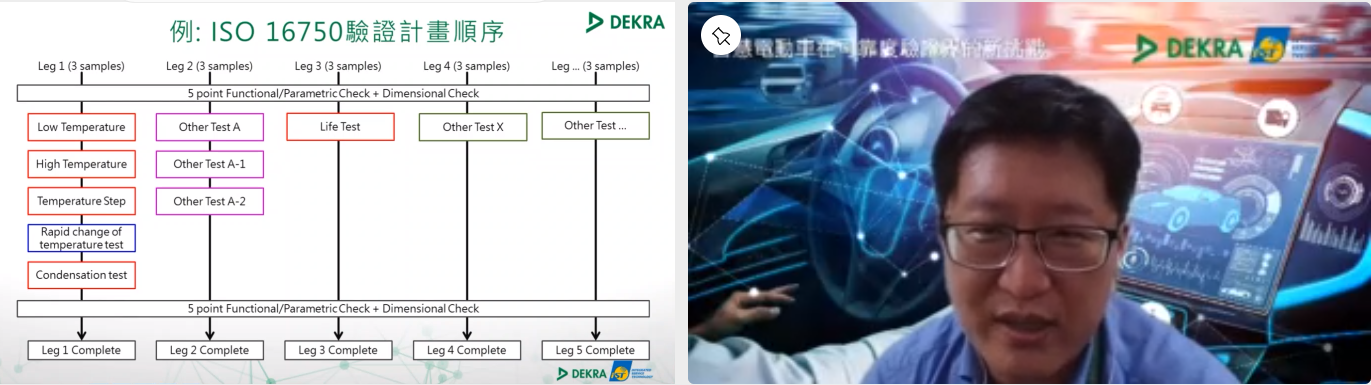

The Automotive Electronics Council (AEC) in the United States also defines different specifications for automotive parts products, including AEC-Q100 for IC chips, AEC-Q101 for discrete components, AEC-Q102 for discrete optoelectronic components, AEC-Q104 for MCM multi-chip modules and AEC-Q200 for passive components. At the system level, the most commonly followed standard for international car regulations is ISO16750, which includes General, Electrical loads, Mechanical loads, Climatic loads and Chemical loads.

The reliability verification of automotive displays or parts is to validate the limited levels under both static and dynamic scenario through different "environmental stresses" in early stage of product design. Dynamic refers to test DUT under operation mode , while static refers to not operate. In addition, the "product life" (RDT-reliability demonstration test) can also be tested through reliability verification. There are 3 ways of verification, including reliability life prediction, reliability life demonstration and field return statistics. Prediction means to estimate with software based on powerful data base; demonstration means to stress products under different aging conditions to estimate product life.

Automotive reliability tests could be divided into 4 types, including mechanical category (Drop, Stone Impact, Dust, Vibration...), climatic category (Temperature, Thermal Shock, Temperature Cycling, Condensation...), outdoor category (water protection, high pressure water, solar radiation, salt spry...) and other categories ( Life demonstration, MTBF prediction, HALT, Acoustic noise.)

For any problem about validation, please feel free to email us. 📧sos@dekra-ist.com