The quality verification of PCB mostly follow the traditional methods, as long as all products after production do not have open or short circuit problems, and refer international standards to execute verification in house. Then, PCB suppliers could self-declare to pass the tests. However, it is not enough for the automotive electronics application, it is necessary to consider the high level of product reliability and safety issues. The international organization, IPC—Association Connecting Electronics Industries, also initiates testing specification and verification program for automotive PCB. In addition, if you want to enter the supply chain of Tier1 automotive manufacturers, you must follow the basic requirements of the automotive OEM in order to prove that the products are in compliance with the regulations.

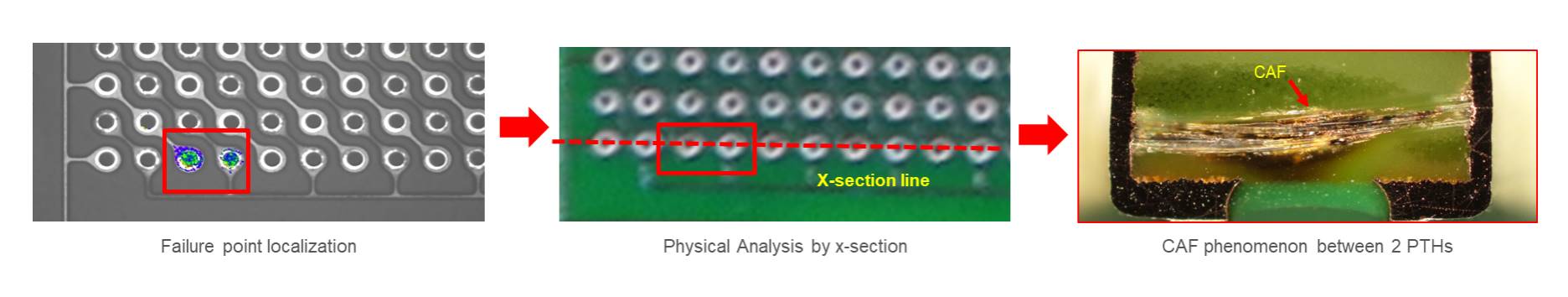

Due to the rise of environmental awareness, people has spent huge amounts of money and manpower to develop alternative energy sources all over the world, and pure electric vehicles (BEV) are one of the projects. From battery pack to charging module, there is no technology that can replace PCB currently, so PCB is still the main basic component in automotive electronics. Therefore, the quality and reliability requirements of PCB applied to the powertrain module will not be lower than other main parts. That is why high-voltage CAF (Conductive Anodic Filament) test is considering at this moment and now couple of Tier1 suppliers has listed 1000V CAF as one of testing condition. DEKRA iST already has rich experience and test capabilities for high voltage CAF test.

<Hi-Volt CAF System>

Furthermore, DEKRA iST offers the one-stop-shop services in High Voltage CAF. We could execute failure analysis for the failed sample and detect the failure location as well.

<CAF Failure Analysis Example>

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com