Before optimized the lead free process in PCB assembly applications, international organizations initiate aggressively to develop halogen free PCBs to deduct the pollution around the environment as well. This new requirement makes PCB and material suppliers to figure out the solutions between RoHS(lead free) and Halogen free regulations implement for E&E industry.

For these requirements, material property is necessary to change, since couple of main issue will occur in halogen free PCBs, include hardening and crisping effects, reduced bonding force of copper foil that leads to reduced pad bond strength, pool quality of drill holes causes material hardening, wick effects increase, speed up of Conductive Anodic Filament (CAF) phenomenon, high-frequency instability, pad cratering and so on. Therefore the design of verification has to be different from the original methodology, and test vehicles must be designed during PCB production in order to monitor PCB quality by each batch. On the other hand, for other material consideration, on pad cratering and pad bonding strength issue, SMD(Solder Mask Design) or NSMD design has to select carefully, and PTH pitch and arrangement are key consideration as well for slowing down the happen of Conductive Anodic Filaments (CAF).

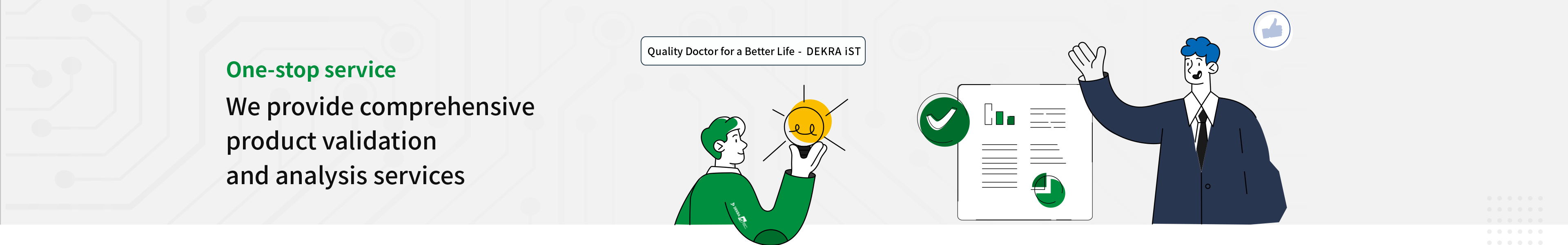

DEKRA iST services portfolio for PCB Reliability Validation:

- Solderability Test

- Thermal Stress Test

- Reflow Simulation Test

- Temperature Humidity Bias Test

- Hot Oil Test

- PCB Insulation Resistance Test

- Insulation Resistance Measurement

- Contact Resistance Measurement

- Dielectric Withstanding Voltage Test

- Ion Contamination Measurement

- Bending Test

- Glass Transition Temp. Measurement(Tg)

- Thermal Shock Test

- Surface Insulation Resistance Test(SIR Test)

- Conductive Anodic Filaments Test(CAF Test)

- Creep Corrosion Test

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com