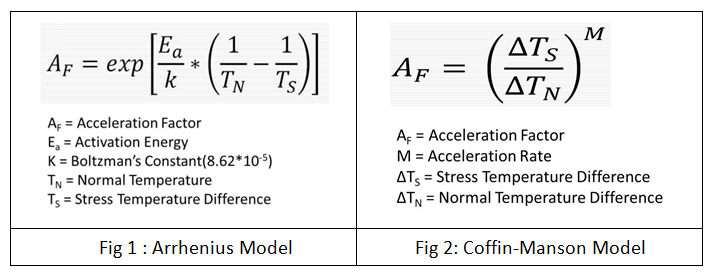

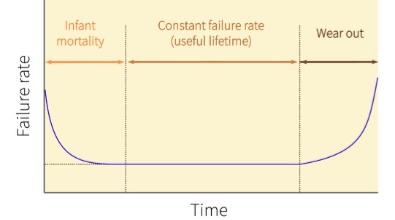

The life expectancy predicted by accelerated life test is used over the years. The most representative model is the temperature accelerated Arrhenius Model (fig. 1). Coffin-Manson Model (fig. 2) is used for Thermal- metal fatigue life test. For lead-free life expectancy, most large foreign companies use the Coffin-Manson Model to test life of PCBA's solder joint.

In general, there are 3 methodologies about evaluating/predicting the life time of electronic system or equipment:

MTBF Prediction

- Usually uses component parameter or the measured temperature as general information and entered into a software program to calculate the product's MTBF (Parts com. or Parts stress)

- Pros Obtain a predicted MTBF figures immediately

- Cons The specifications of parts change rapidly, and the prediction method has not been appropriately adjusted with the evolution of parts or products. While the parts assembled to the system, the individual impedance, voltage/current, and other factors cannot be completely simulated. Thus, the predicted life data normally regards as reference.

Reliability Demonstration Test

- Popular model: Arrhenius model- Equation 1

- Pros Test report + Statistics data generated, and has a certain amount of accumulated experience for easily accepting by clients or buyers. Reliability Demonstration Test

- Cons The life cycle of current products is short, but the ICT clients require to reach 5 years committed life in recent years. Therefore, demonstration test will take long time for execution and influence time-to-market plan. To determine the appropriate stress temperature could speed up the testing duration.

Field Data Collection

- Directly collect and analyze the information, which customers returned products or described the failure phenomenon.

- Pros Reality and accurate data

- Cons Since the products were sold on the market, the collected data only can be used as a reference for next generation or new design of product.

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com