編輯器

Generally speaking, a flaw or weakness of product is easier to fix during developmental stage. If the product already went into mass production, each problem is getting complex and very difficult to fix. During this low-margin age, if a product shows signs of malfunction or failures in the warranty period, the lost of cost and reputation are both incalculable easily. In the 1990s, some large American international companies (including Hp, Dell, Cisco, Nortel, Tetronix, Motorola) used HALT testing for newly developed products to quickly find any potential defects or weaknesses in the design or production as well as make modifications to lower costs during warranty, increase product reliability, and shorten product launch.

Highly Accelerated Life Testing (HALT)

The purpose is based on the premise of product failure, to stimulate design defects, and by optimizing product selection and design to improve product reliability; therefore, it is usually used during the initial stage of product development and find out the design limit of product.

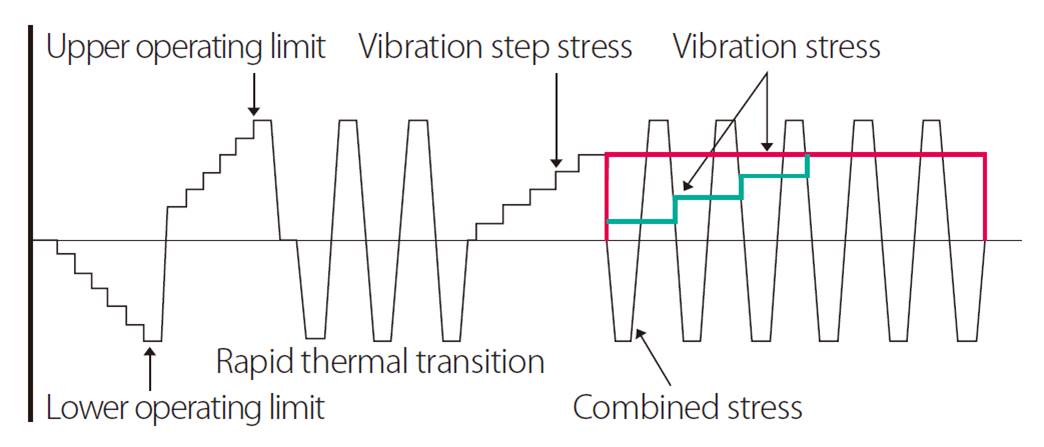

HALT uses a step stressing technique to accelerate the life of the product. Stressing includes: vibration, high/ low temperature, rapid temperature cycling, combined stress, on/ off cycling, voltage limits and frequency

<General HALT procedure>

Highly Accelerated Stress Audit/ Screening (HASA/HASS )According to statistics from America's GE company, failure probability of a new product are 33% from design defects, 34% from unsuitable component selection, and 33% from production process; Honeywell's investigation about mature products entering the market showed that 60% of the failures are due to bad quality components and 40% from unstable production . Therefore, better production control on components and manufacturing process can effectively control RMA percentage.

In general, when a product shows failure in the field, usually there are already hundreds or thousands of that production line out on the market. Therefore, taking advantage of the results from HALT testing during the designing stage will increase product standards and by inducing the results into HASA/ HASS testing will bring quality control on mass production.

HASS(Highly Accelerated Stress Screen)

HASS is used to screen 100% products in order to find out defective product and eliminate fragile product, since these products may have early failure issue in life cycle(infant mortality period); before you use HASS for screening products, the HALT result is necessary and then, you could find out the appropriate conditionsㄡ

HASA(Highly Accelerated Stress Audit):

The difference between HASA and HASS, HASA is not 100% tested all products and need to pick up samples by random; before you use HASA for verifying products, HALT result is necessary as well and then, you could find out the appropriate conditionsㄡ

Benefits of HALT/ HASS/ HASA

- Potential flaws and defects of the product will emerge and can be modified during the design stage.

- For mass production screening, HASS and HASA can be used for screening early failed products.

- HALT/ HASS/ HASA can be used to reduce failures on the market and decrease repair costs.

- The results are stored in development database and can be used for reference in future development to save cost and time.

Machine Specifications

- Temperature:-100℃ to +200℃

- Temperature change rate:>50℃/minutes

- Axes excited:3 Linear, 3 Rotational

- Vibration frequency range: 10 Hz To 5 KHz

- Vibration level:Up to 50 GRMS

- Inside dimension: 136(W)*137(D)*91&139(H)/cm

- Vibration table : 122(W)*122(D)/cm

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com