Different transducer is used for each kind of sample accordingly, and DEKRA iST has comprehensive transducers from LF 15Mhz to HF 230Mhz even the UHF type.

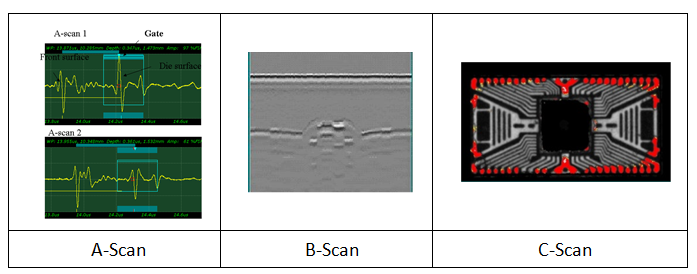

Inspection Methods:

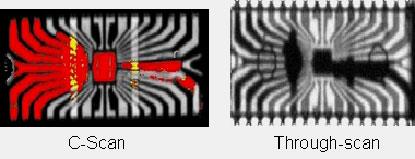

1. Pulse Echo Method

- A-scan: Inspection with waveform displayed on oscilloscope

- B-scan: Inspection with vertically x-sectioned 2D image

- C-scan: Inspection with horizontally x-sectioned 2D image after focus.

2. Through Transmission Method

- Through-scan: Inspection with transmitted signal

Major Application:

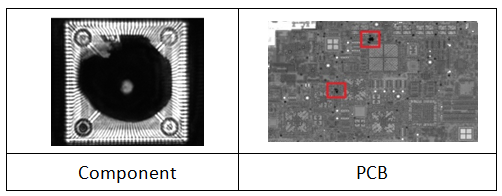

For most of molding-compound-package component and multi-layer laminated structure design (such as Printed Circuit Board, PCB), the ultrasonic of SAT is used to detect whether there is delamination or crack inside of body. At present, a tiny gap of about 0.13 μm can be detected as well and SAT can be applied to the following analysis request:

- Component/PCB/Substrate failure analysis

- Component package/PCB laminated structure quality verification

- Process parameter verification (reflow heat damage)

- Incoming material inspection (IQC) or outgoing random inspection (QC)

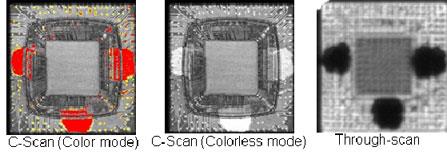

SAT Real Cases:

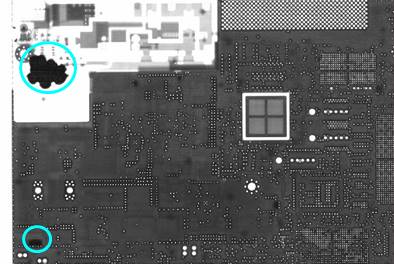

<Substrate delamination of BGA substrate>

<Substrate delamination of BGA substrate>

<Die & Paddle & Lead delamination inside of TSOP component>

<SAT T-Scan for bare PCB>

SAT Limitation

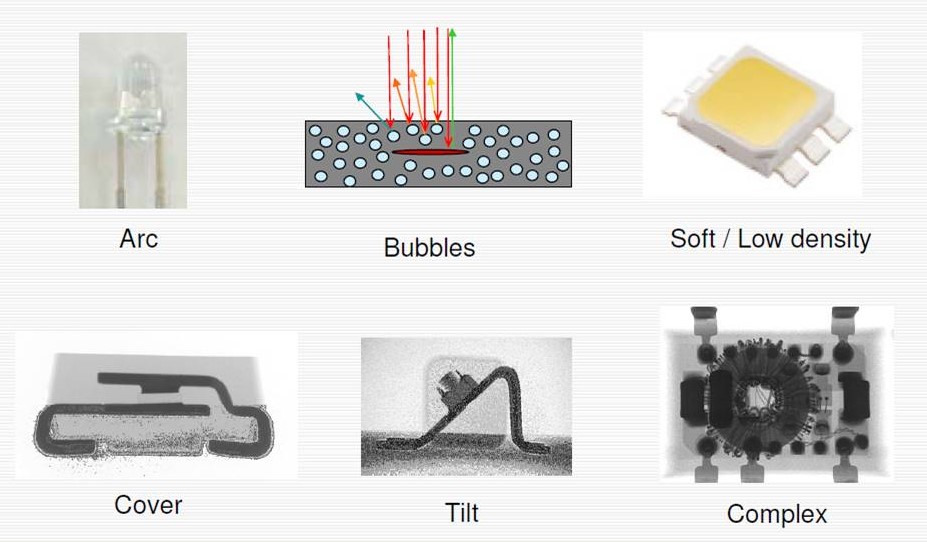

SAT detect abnormal points through ultrasonic reflection signals, so if the surface is rough or with bubbles, it will affect the half of the result. Therefore, the following components are not suitable for SAT analysis.

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com