Major Applications

- Detection of part IC package defects, such as appearance integrity, the black gum cracks, pin deformation or discoloration.

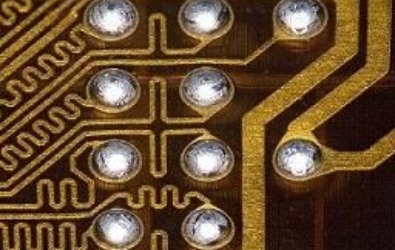

- Detection of potential PCB defects, such as nodules, weave exposure, glass fiber exposure, solder mask, text.。

- Detection of potential detects in electronic products, such as poor soldering.

- Detection of potential detects in electronic products, such as poor soldering.

- Appearance check and analysis of active and passive components.

- Analysis and measurement of all materials

KEYENCE VHX-2000 Specification & Features

- Magnification:20X~1000X

- Tilt angle:0°~60°

- Rotation:180°

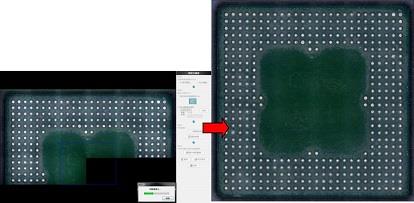

- Highly Composite Images

<Under high magnification observation, a fully focused image can also be obtained.>

- Fill Light Function(LED light source)

<The Fill Light Function with XY table moving system could give the full-angle observation. For via hole of PCB, the Fill Light function can be irradiated from bottom and check whether the via hole is plugged or damaged.>

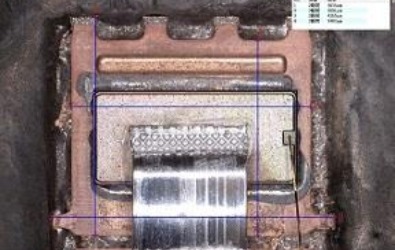

- High Definition Dimensional Measurement

<Completely dimensional measurement includes length, angle, area and so on, and satisfies various request from clients.>

- High Speed Automatic Images Composite

<Record and assemble images automatically to obtain wide-angle images through the XY table moving system>

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com