In general, the shock test can be divided into the following three types of waveforms according to different requirements and usage environments:

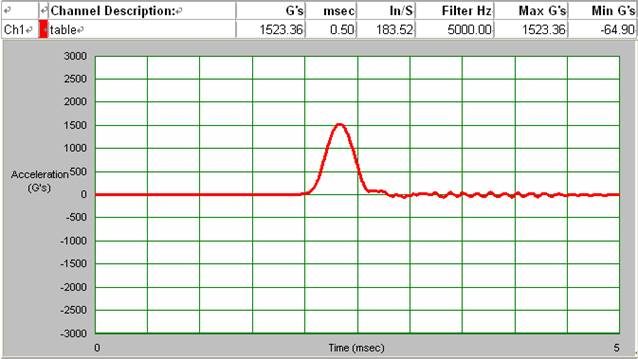

- Half-Sine Wave: It is widely used to look for the material limit of the product's mechanism. In addition to verifying the strength of the product itself, it can also verify whether the interconnected strength both composite material and assembly process (such as solder joint) can meet the requirements of quality.

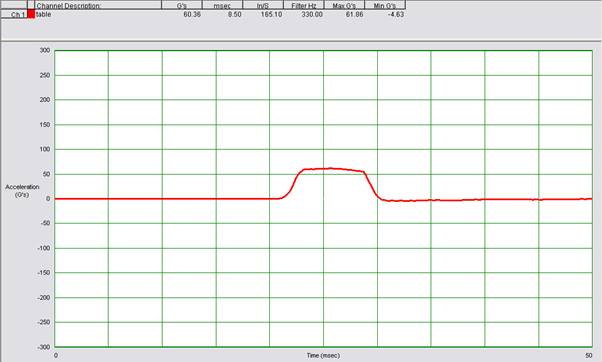

- Trapezoidal Wave (Square Wave ): It is often used to look for the optimized package design of product protection, and simulate the impact strength of the product under the protection of packaging materials.

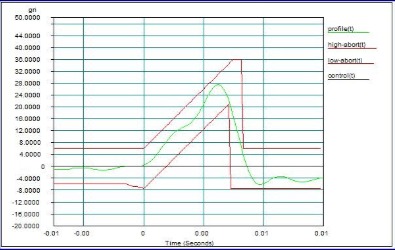

- Saw-tooth Wave: There are two kinds of saw-tooth wave, Saw-tooth leading edge and Saw-tooth trailing edge, and both are generally used for product validation in military, aeronautical applications or other special environments.

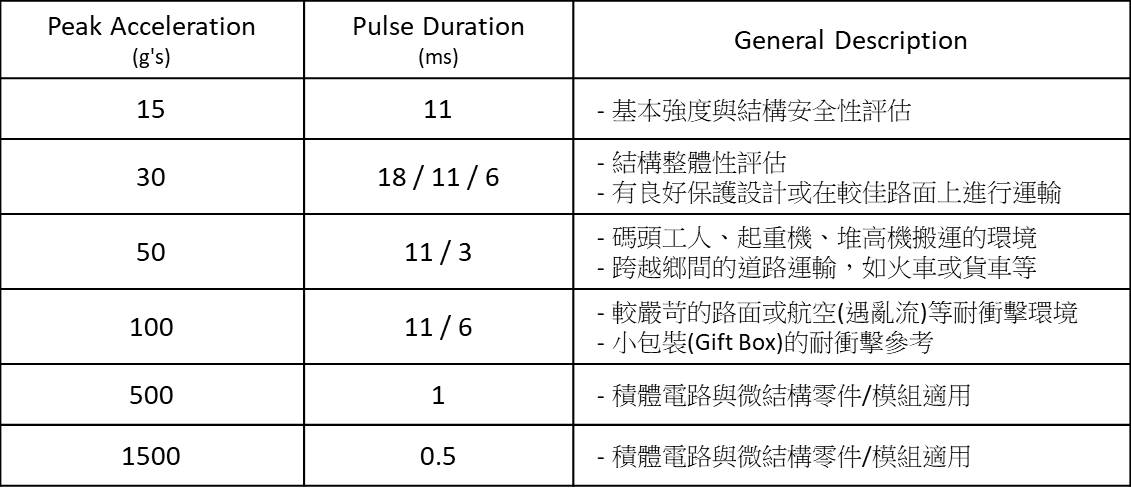

<Table1 General Shock Conditions>

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com