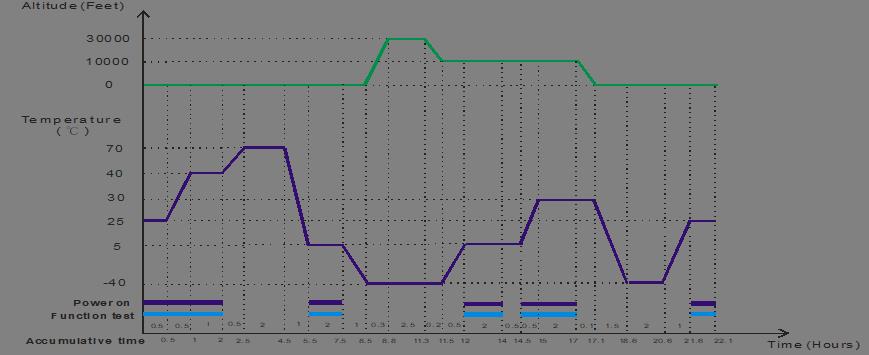

The International Electrotechnical Commission (IEC) has recommended testing procedure for pre-test treatment, post-test treatment, temperature and air pressure changes, etc. For example, in a low-pressure environment, temperature transmission is not easy, so before air pressure changes, It is recommended to execute the temperature change first, make the product temperature reach the testing condition and then, execute pressure change. (See the example below)

<Temperature / Altitude Test Profile Example>

In addition, there are mostly 2 kinds of test application: Transportation environment Test and Operating Environment Test. The transportation environment usually accompanies with low temperature and low air pressure as validation conditions, and operating environment accompanies with high/low temperature and low air pressure.

To make all your PROBLEMS SOLVED, we provide professional consultant and service.

For more information or service, please feel free to email to 📧 sos@dekra-ist.com